Vehicle Control Unit – VCU is the vehicle’s main control system. It is based on our proprietary and modular HW&SW platform.

VCU can be used as a single control unit or two completely redundant control units. The same hardware can also be used in the propulsion converter’s control units. Redundant configuration can be found e.g., in Končar’s TMK2200 series tram cars.

VCU communicates with all distributed intelligent units, driver-machine interface (LCD panels in driver’s cabin) via CAN, Ethernet, RS485, or MVB busses. WTB bus is used for communication between vehicles in composition.

It can be found in tramcars, trains, and locomotives.

Since there are specific requirements for each rail vehicle, VCU can be delivered in different configurations to match every vehicle.

- Control

- Measuring

- Sequencing

- Protection

- Supervision

- Communication tasks in the whole vehicle

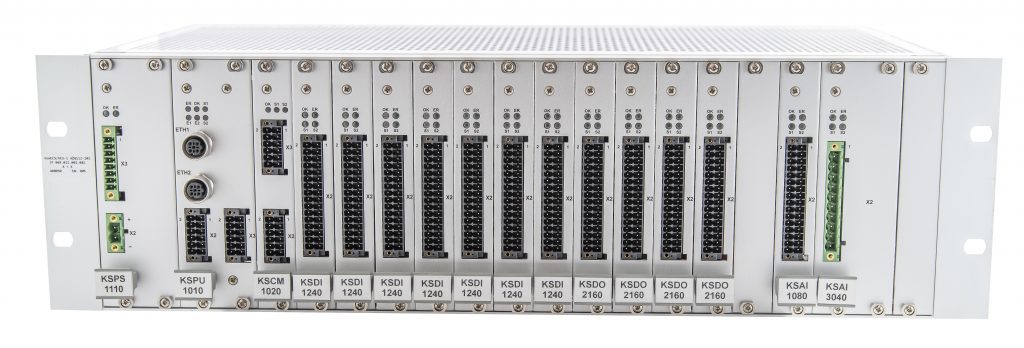

VCU rack consists of:

- Electronic modules

- Power supplies

- Motherboard (buses)

- Supply subsystem, which consists of power supplies and their control circuits

- Motherboard

- Central processing module

- CAN communication module

- Voltage and current measurement module

- A digital speed measurement module

- Synchronization module

- Impulse generator module

- Analog inputs and outputs module

- Digital inputs and outputs modules

- Pulse amplifier module

- Operating temperature range: -40 to +85 °C (IEC 60571:2006, Class Tx)

- Shock and vibrations: IEC 61373:2010, Category 1, Class B

- Meets requirements of the following standards: EN 50155:2007, EN 50121-3-2:2006, EN 61000-6-2:2007, EN 61000-6-4:2005

- Programming tool: Grap-IDE

VCU Modules