Other articles

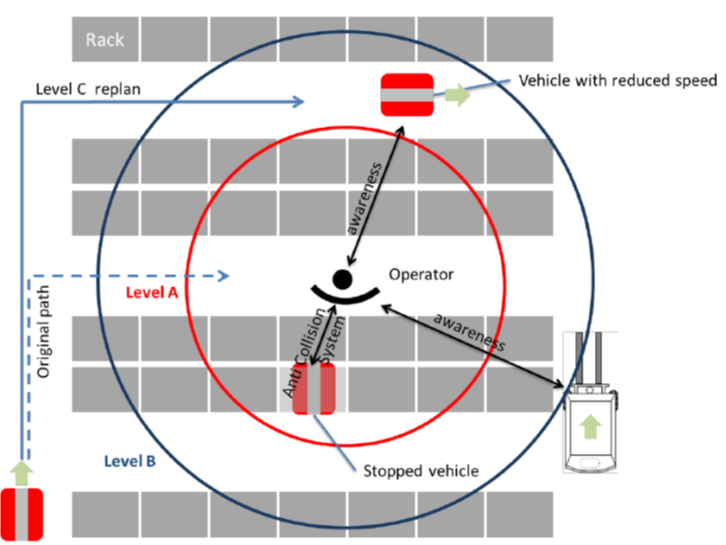

The safety concept is partitioned into the following three levels:

- LEVEL A

A virtual circle around the human operator acts as a simulated electromagnetic pulse. No movements of mobile robots are allowed within this circle. Even if the human is moving around, all mobile robots will stop at a safe distance from the human. This level ensures the intrinsic safety of the overall system.

- LEVEL B

At this level, approaching robots do not yet impose a threat but their speed is reduced to avoid potential upcoming dangerous situations. The promising applications of this approach are forklifts. The driver of a forklift is warned about the presence of a colleague and the speed is limited until the distance allows safe use of full speed.

- LEVEL C

Re-planning of human and robot paths is outside of the scope of the Safety Vest System but is indicated here as an optional and desirable extension that could reduce SVS activations and thus increase the overall system availability.

To realize this concept and maintain safety for the humans while they work in close collaboration with mobile robots, a mandatory Safety Vest must be worn, and the robots must be equipped with an Emergency Stop Module.

The Safety Vest can be expanded with non-safety components to enable implementation of additional functions besides slowing down and stopping robots such as:

- localization of the human and communication of this information to the fleet management system (FMS) to re-route robots away from humans (Level C at the picture above)

- warning the human of the approaching robots e.g., via visual and audio indications

- displaying positions of nearby robots e.g., via augmented reality (AR) glasses

- assisting the human in accomplishing tasks by displaying instructions on a handheld device or AR glasses.

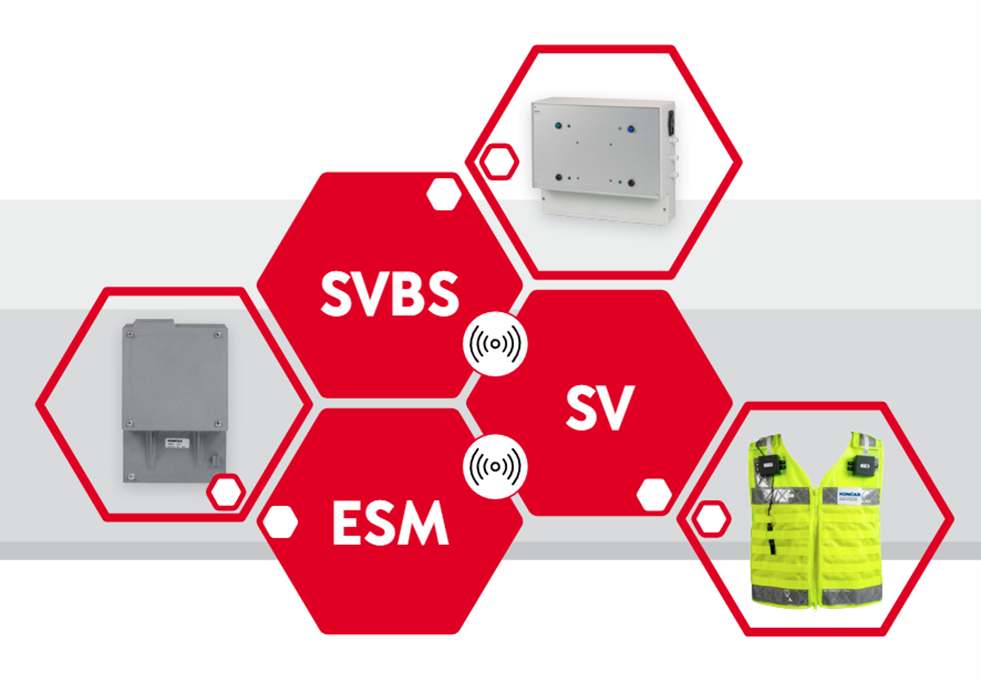

The safety functions of the Safety Vest System are implemented by three devices:

- Safety Vest (SV) – worn by the human,

- Emergency Stop Module (ESM) – installed on the machines, and

- Safety Vest Base Station (SVBS) – as a part of the safety infrastructure.

In the next blog post, we will share more details about the structure and main constituents of the Safety Vest System. Stay with us…

KONČAR – Electrical Engineering Institute is mainly focused on providing solutions in the area of railway and electric power equipment and systems. However, recognizing the huge potential of the developed technology of Safety Vest System, we are publishing this blog post series to attract partners interested in bringing it to the market.

This work has been supported by the European Union’s Horizon 2020 research and innovation program under grant agreement No. 688117 (SafeLog). SafeLog project consortium was comprised of:

- Karlsruhe Institute of Technology

- Swisslog

- Czech Technical University in Prague

- The University of Zagreb, Faculty of Electrical Engineering and Computing

- Fraunhofer Institute for Material Flow and Logistics

- KONČAR – Electrical Engineering Institute