KonLab series are high power lab converters used as a power supply for a variety of different three-phase loads. KonLab series converters are a version with 120 kVA nominal power output. Its output voltage and frequency can be easily and independently adjusted using intuitively designed HMI.

KonLab series are high power lab converters used as a power supply for a variety of different three-phase loads. KonLab series converters are a version with 120 kVA nominal power output. Its output voltage and frequency can be easily and independently adjusted using intuitively designed HMI.

KonLab modular hardware and software platform is developed to be highly flexible which provides an easy adjustment to customers’ needs in terms of different power outputs, different communication interfaces, various control mode parameters: e.g. voltage, current, power, and frequency.

CAN, RS485 and Ethernet communication interfaces are available (others on request) and optional remote access.

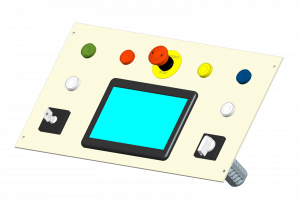

The front side consists of several pushbuttons, signal lights, and touchscreen LCD panels (7‘’ or larger on request), used for setup and monitoring of one or more converters.

KonLab signalization can be integrated into the existing laboratory (safety) signalization system. One of the special features available on request is a low noise operating mode, which improves the quality of the work environment.

Features

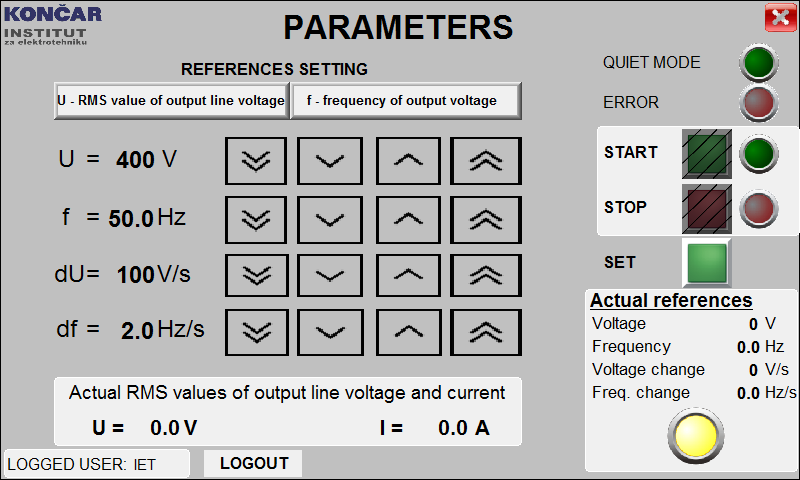

3-phase, variable voltage and frequency output with high-resolution adjustments

3-phase, variable voltage and frequency output with high-resolution adjustments- High output power 120 kVA (other power ratings on request)

- Multiple operating modes

- Galvanic isolation of loads

- High-efficiency power conversion (over 90%)

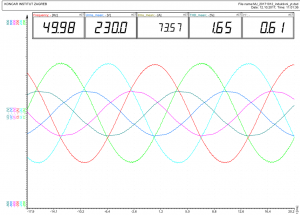

- Very low output voltage THD (<3%)

- Robust mechanical design

- High reliability and easy maintenance

- 7” or larger HMI interface for control and local monitoring purposes

- Remote control and monitoring available

- Overvoltage, overcurrent and overtemperature protection

- Integration into laboratory safety signalization and control systems

- Low noise

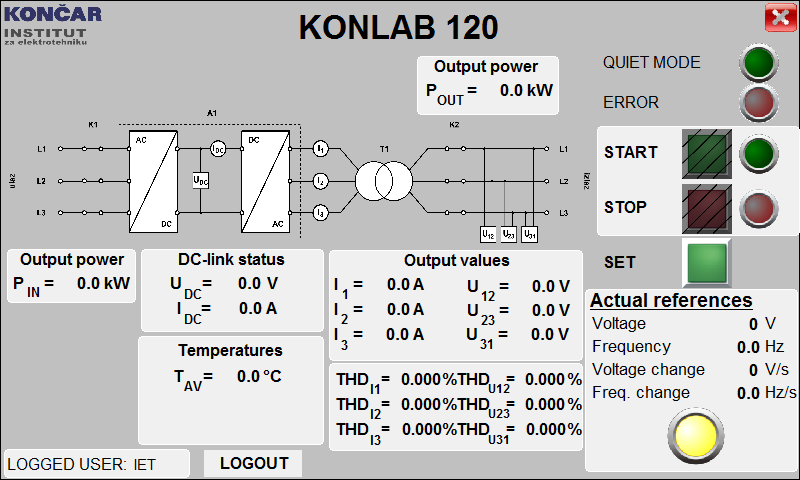

HW&SW protection of vital components

KonLab comes with hardware and software-based protection on AC input and output to ensure prevention from explosions, fire, or other damage that may affect the converter’s components during the operation or cause injuries to operators. Protection status and converter operation status are shown on HMI, signal lights, and additional signal tower if installed. All statuses can be forwarded to consoles for remote operation or a higher-level (SCADA) system via MODBUS (RTU/TCP) or CAN connection. Operating errors are stored locally, in form of long-term and scope-like short-term recordings.

Noise reduction

Several techniques are used to reduce the noise of the KonLab converter. Critical components are put on rubber buffers. Cooling air (intake and exhaust) can be ducted outside of the laboratory, where the converter is installed.

The speed of cooling fans is controlled depending on ambient temperature, the temperature of critical components, and load current.

Signalization and remote control

On request, the converter’s signalization system can be integrated into the existing laboratory safety signalization system. It is configurable according to the customer’s needs. Several converter push-buttons and signal lights are also configurable.

On request, the converter’s signalization system can be integrated into the existing laboratory safety signalization system. It is configurable according to the customer’s needs. Several converter push-buttons and signal lights are also configurable.

On request, the converter can be installed in a remote location and equipped with several remote control consoles.

The converter can also be integrated with „high level” (SCADA/data acquisition) systems.

Human-Machine Interface

Human-Machine Interface is used for control and monitoring of converter operation. It contains several screens, but the number of screens, layout, and functions can be fully customized or changed at any time according to customer needs. Preprogrammed voltage/frequency operating sequences are also available on request.

Download the brochure to find out more!