The probability of faults is relatively high for rotating machines working at upper acceptable limits of operation. These faults are caused by electrical, thermal and mechanical, as well as by operational and environmental conditions. The majority of monitoring and protective systems use digital processors that allow utilization of complex criteria for determining the presence of the faulty state of the machine. Besides the fault detection, fault diagnosis that determines the cause and location of the fault also requires expert knowledge.

The numerous studies have shown that measurement of the magnetic field inside and/or outside of the machine may detect faults. Typical examples are the inter-turn short-circuited winding of stator and rotor, broken rotor bars and the ring of the squirrel cage and eccentricity.

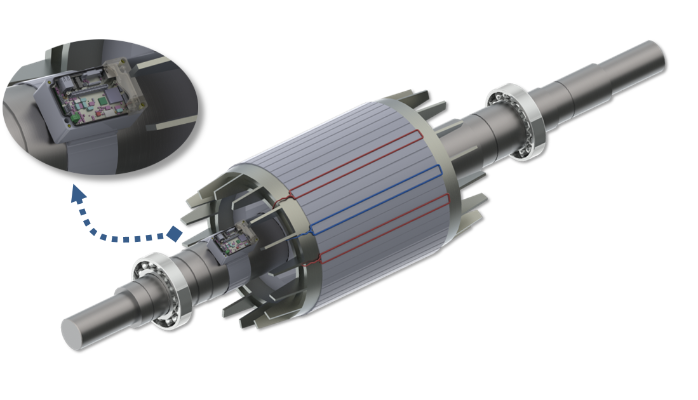

A new solution called Energy Harvester for fault diagnosis is based on the magnetic field measurement using measuring coils installed in the air gap of the machine. The measuring coils can be used for fault detection and diagnosis, and also as a power supply for the diagnostic system.

Application field

One of the application areas where this innovation can be used is machine rotor. Wind generators or any AC machines with winding made of coils can benefit from this solution.

So how does it work? Due to the pulsations of the main magnetic field, the measuring coils contain induced voltages. The coils are embedded on the rotor of the machine. With the serial connection of the coils, it is possible to ensure the sufficient level of voltage for supplying the measuring device. Such device supplied with energy from the main magnetic field is capable to measure electromagnetic, thermal and mechanical quantities.

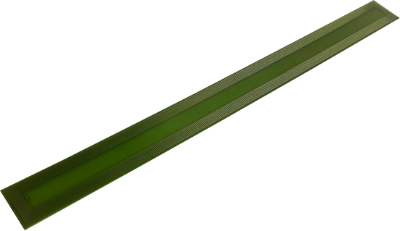

Measuring coil for installation on AC machine

Problems addressed with Energy Harvester

Equipping a machine rotor with Energy Harvester means supplying a “smart rotor“ with power using a specific diagnostic probe. “Smart rotor“ can be seen as a rotor with built-in electronic control or regulatory elements, measuring probes, communication circuits and power supply of these elements. The fluctuation observed in the magnetic field between stator and rotor, i.e. within an air-gap, is used at the same time as the power supply for the smart rotor electronic circuitry and as a measuring probe for screening an AC machine in operation.

The first issue that Energy Harvester solves is the possibility of harvesting enough power that can in the second step supply demanding operations of the “smart rotor“.

The second technical problem solved with the solution is the way of positioning and combining multiple straight inductive probes – from which the micro energy harvesting device is composed – within an AC machine’s air gap. According to our findings, the invention speaks for micro harvesting device position within the air-gap in order to give maximal power yield while minimizing the airflow disturbance. Moreover, the energy harvesting proposed by this new solution is almost continuous.

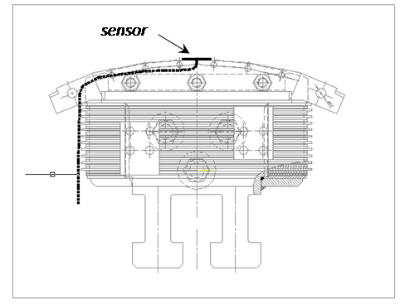

Position of measuring coil installed on the rotor pole shoe

Our research obtained by FEM model has shown that that with the optimal positioning of the measuring coil in the air gap, it is possible to obtain adequate voltage necessary for power supply. The laboratory results have proven that it is possible to obtain sufficient amount of energy for power supply of the measuring equipment on a rotating part of the machine.

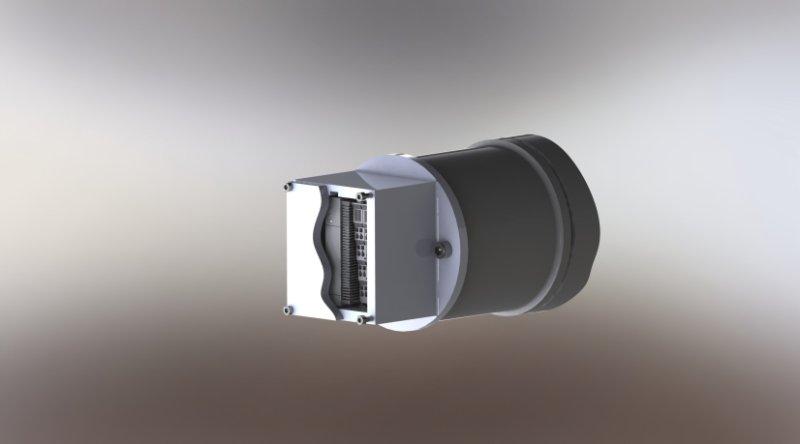

Measuring equipment mounted on machine shaft

The benefits of Energy Harvester are straightforward for all stakeholders involved in effective machine operations:

- One of the critical and expensive machine parts can be managed with a system that generates power by itself and then uses it for powering the monitoring equipment

- The solution is non-destructive, which means it can’t damage the machine

- The probe used is passive in its nature and has a very lightweight

- The solution is very easy to install

And the conclusion is …

The primary use of a micro energy harvesting device is to serve as a power supply for the electronic circuitry built on a rotor of an AC machine. The current waveform generated by one or more straight inductive probes is used for the diagnostic and control of the AC machine operation. This opens a lot of opportunities in the field, such as powering of wireless sensors of a rotor during the operation. For the machine operators, this means they can monitor and diagnose critical machine faults with a cost-effective, but a very efficient self-powered diagnostic system.