Problems that can occur in electrical machines are shaft currents and voltages. Due to the asymmetry of the magnetic field in the machine, a voltage in the shaft can be induced, which, depending on the type of machine, its size, and load, varies in amplitude and frequency composition. These asymmetries can cause a potential difference between two points on the shaft which leads to shaft voltage and thus eventually shaft current flow.

Problems that can occur in electrical machines are shaft currents and voltages. Due to the asymmetry of the magnetic field in the machine, a voltage in the shaft can be induced, which, depending on the type of machine, its size, and load, varies in amplitude and frequency composition. These asymmetries can cause a potential difference between two points on the shaft which leads to shaft voltage and thus eventually shaft current flow.

The low impedance of the circuit consisting of a shaft, bearing, oil film, and other structural components, can cause shaft current flow which leads to bearing destruction. Continuous measurement and analysis of shaft currents and voltages can prevent major faults.

Our solution in the form of an easy-to-install shaft current and voltage protection relay (SCVP) provides measurement and analysis of values that may damage the generator bearing. Monitoring of shaft currents and a quick response to the increased amplitude of these currents is an easy way to protect the expensive power generation equipment.

System overview

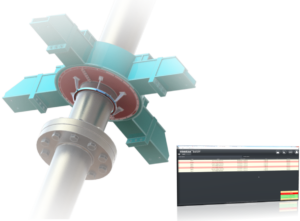

The architecture of the SCVP system is a multi-channel processing unit with a real-time controller combined with input and output analog and digital modules. The processing unit is a fast and reliable industrial PLC, designed for harsh conditions and environments. It has all the necessary certificates and references for use with electrical machines.

SCVP system has a wide measuring range, signal frequency range up to 10 kHz, and very low measuring error. High sensitivity for input currents and voltages allows measuring of relatively small signal amplitudes. The shaft current is measured by the special current measuring transformer installed around the shaft, usually under lower generator bearing.

The solution can be used with all types of current measuring transformers. The processing unit conducts FFT analyses of the input signal with high resolution and sampling frequency. Depending on the chosen configuration, if the analyzed data exceeds a certain value, the appropriate signals are forwarded to the digital outputs or are stored in a database.

Benefits

Bearings damaged by shaft currents will eventually show increased vibrations which means that the damage is already done. The main advantage of our SCVP system is that it indicates a problem before major bearing damage has occurred. This is the reason why SCVP is recommended as an additional monitoring system along with the classic protection relay function.

Additional benefits include:

- sensor and system implementation performed with minimum interference in machine operation

- integration with other systems like SCADA using standard industrial communication

- innovative technology which connects local HMI, a database for long term archive and web server for a compact product

- intuitive data presentation and remote access to the system using standard Internet browsers

- spectral analysis (FFT) using instrument transformer which can be used to set custom alarms for critical values

- integration of multiple users accounts into one user application